PRO-PLUS-E-UP-250

RO pure water: desalination rate as high as 95-99% , Conductivity ≤10μS/cm

Ultrapure water:

resistivity 18.25MΩ.cm@25°C,

TOC: <3 ppb,

particles (>0.22 um) <1/ml,

microorganism <1 cfu/ml

Product feature

Ø Ergonomic design, the machine is beautiful and generous in compliance with GLP requirements

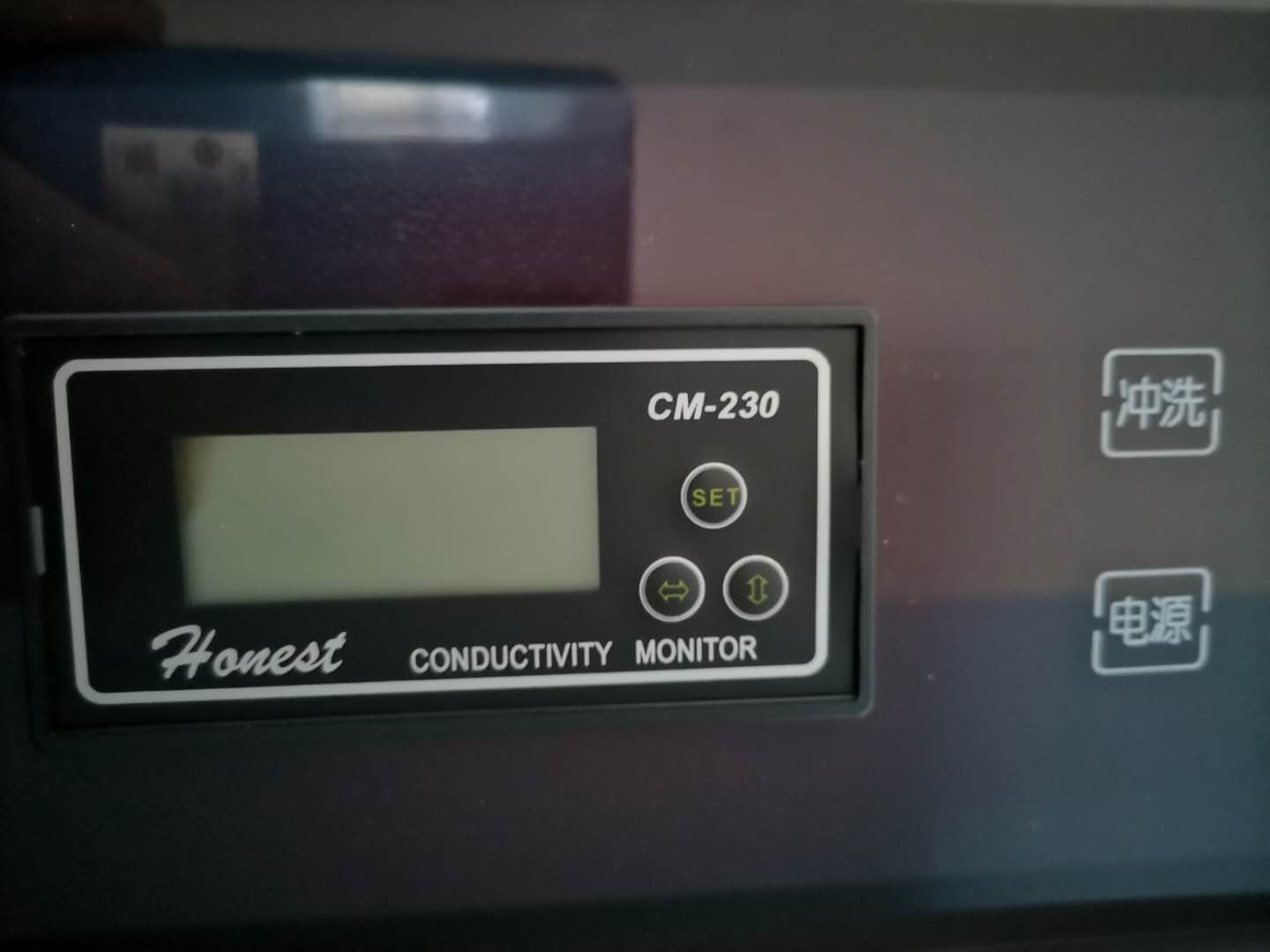

Ø Fully automatic microcomputer control system, online water quality monitoring system, and filter element online monitoring

Ø New quick plug-in connector, filter column replacement and maintenance is more convenient for the electrical and water channels to be completely separated.

Ø Fully automatic RO membrane anti-fouling washing program and regular washing program to prolong the service life of RO membrane

Ø Power, water source, pump, flush, water shortage, full water status display, understand the machine running status

Ø Floor-standing design, with movable and fixed feet at the bottom, making installation and movement more convenient

Ø RO water, ultra pure water, two kinds of water outlets

Ø Free TDS water quality test pen

Parameter

Water rate | 250 liter per hour |

Production speed | 4.3 L/min(with pressure barrel) |

The water requirements | Urban tap water, inlet water pressure: 0.15-0.5mpa, water temperature 5-40℃,TDS<200ppm |

RO water Parameter | |

Ion rejection rate | 97%-99% (when using a new RO membrane) |

Organic matter rejection rate | >99% when MW>200 Dalton |

Particle and bacterial rejection | > 99% |

Application | Clean glassware |

UP water Parameter(ASTM TYPE I grade water) | |

Resistivity (25℃) | 18.25 M Ω. Cm @ 25 ℃ |

Heavy metal ion | < 0.01 ppb |

Total organic carbon (TOC) * | <10 ppb |

bacteria | < 1 cfu/ml (with terminal filter) |

Particulate matter (> 0.1 microns) | <1/ml |

Application | All kinds of physical and chemical testing, biochemical analysis, blood examination, microanalysis, flushing special, HPLC, IC, GC, analysis experiment |

Electrical requirements | 110-240V/50-60Hz, 48-72W |

The system configuration | Host machine (including 1 set of purification column)+100 L pressure water storage tank +TDS pen + accessory bag |

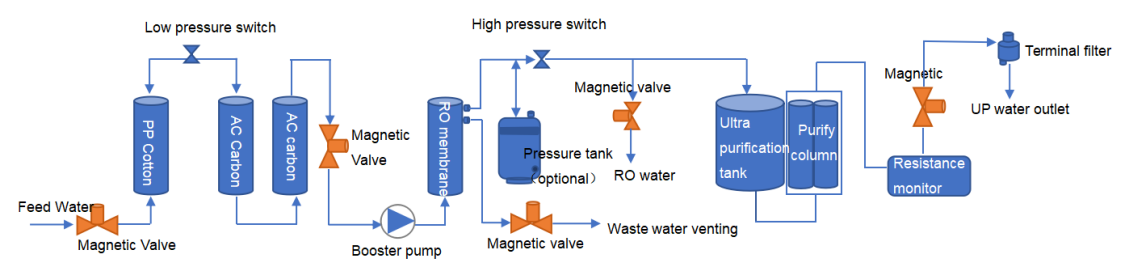

Filter function

PP cotton filter | | remove impurities (greater than 5 micron) such as suspended solid, rust, sludge, colloid, etc. | |

Granular activated carbon filter | | remove color, odor, residual chlorine and heavy metals | |

Reverse osmosis membrane | | filter out <1nm pollutants, ions, particles | |

Ultra-purification tank&column |

|

| ion exchange resin bed, H+ and OH- ion removal |

0.2μm terminal filter |

| final removal for < 0.2μm bacteria | |

Process

Product consumables list

No | Filter element | Replace cycle | Quantity | Remark |

1 | 20’’ 5 μm PP cotton | About 4-6 month | 1 pc | |

2 | 20’’ Refined activated carbon | About 4-6 month | 2pcs | |

3 | 600 GPD RO membrane | About 1-2 years | 3 pcs | |

4 | 25 L ultra purified tank | About 50 tons | 1 pc | |

12’’ ultra purification column | 2pcs | |||

5 | 0.2um terminal filter | —— | 1 pc |

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Lucy Wang

Phone: +86 18916636634

E-mail: shldupw@gmail.com

Add: No.517,Xinlai Road,Xuhang Town,Jiading District,Shanghai,China